Some of the world’s top rice-producing countries include India, Bangladesh, the Philippines, Vietnam, Pakistan, Thailand, and China, with China being the larger producer of most. In an average year, the Asian country harvests over 210 million a great deal of the grain. While everyone understands that rice is an important crop for the global food industry, many people don’t realize what is really behind its production.

The fact is that when harvesting a rice crop, a huge selection of plenty of biomass waste is generated. The biomass waste is largely from the inedible rice husks, otherwise known as rice hulls, that protect the editable grains for that elements. For each ton of rice harvested and processed, approximately .2 tons of biomass waste is generated. So, it’s not difficult to visualize why there are plenty of charcoal making machine.

Something essential to know is that rice husks have little in common with wheat husks and oat husks. The husks can’t be utilized for soil fertilizer in their natural state due to their high silicon content. They have to be burned first before they could be plowed back into the ground and the incineration process produces lots of carbon pollution.

Fortunately, as a result of modern engineering advancements, it is now easy to convert silicon-rich rice hull biomass waste into high-grade biochar using rice hull carbonizers, or biochar machines. The best thing about those machines is they are energy-efficient and don’t produce any toxic emissions during operations as a result of modern filtering systems. Click here to know more: https://bestoncompany.com/.

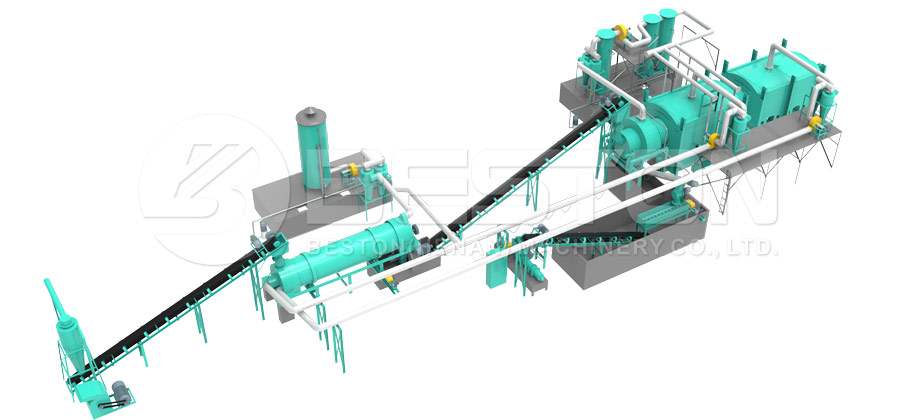

The key areas of a modern day biomass waste carbonization plant include crusher, shredder, carbonization host, drying machine, spray tower, dedusting system, and gasifier. The drying machine is necessary to remove any excess moisture content from rice husks before they enter into the carbonization furnace. Moisture amounts of biomass waste have to be below 18% for effective carbonization.

The most important end products from rice hull carbonization are biochar and biogas. In most setups, the biogas is utilized directly as fuel in a biomass waste processing center to reheat reactors. The biochar produced, meanwhile, could be reformed into high-carbon charcoal briquettes or sold towards the chemical industry, pharmaceutical industry, metal industry, as well as others. You can actually convert biochar into activated carbon, and that is a sought-after purification agent by the wastewater treatment industry. More information on coconut shell charcoal making machine here.

Rice hull carbonizer prices vary in line with the specs of your machine. The hourly processing capacity, working method and automation measure of a device all use a big impact listed price. There are many leading charcoal making machine manufacturers functioning, but it’s generally wise to stick to machinery from established global brands like Beston. You can get price estimates to the manufacturer’s latest biomass waste plants online.

Before making an investment in any type of rice hull carbonizer, it’s advisable to make a biomass waste to bio charcoal business plan. Writing this type of plan can also help your organization to get into government subsidies and startup capital from private investors. The funds raised will help cover the cost of all the carbonization furnaces and processing equipment you should run your organization. Visit the site: https://bestoncompany.com/biochar-production-equipment/.