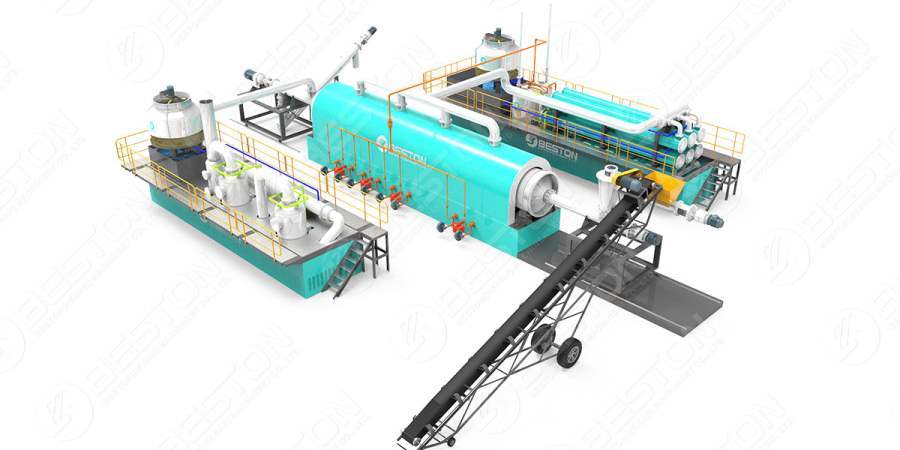

In the type of fully continuous waste tire plants, additionally there is pretreatment systems, along with a continuous feeding and discharge system. They are easily controlled with the use of PLC tech. However, the principle system related to the plant may be the continuous pyrolysis section. Our article features some more technical specifics about the continuous pyrolysis plant.

The continuous pyrolysis plant is commonly used for processing waste tires. It converts them into both carbon black and fuel oil so that they can be recycled. Ever since the discharge and feed are continuous, the plant can stay operational and never need to stop. This further saves both time and energy.

Since PLCs are involved, this too further adds to a decrease in labor costs. So that you can have the machine operating in its optimum condition of continuously feeding and discharging, the types of materials must be shredded in the small pieces. This is done in an attempt to maintain the byproducts from being intertwined. Click here to know more: https://bestoncompany.com/.

However, just before the process begins don’t forget to separate the steel wire. This equipment is quite easy to give while there is generally an abundant source of tires throughout. If you’re having trouble, you can even secure contracts with firms that cope with vehicles so you can get their old tires.

As we’ve said before, you’ll must remove the wire. This can be accomplished with the aid of a wire pulling machine. The equipment works and automatically pulls the wire in the tires. So that you can shred the fabric, you’re also gonna want to use a specialized shredder. The shredder activly works to shred the tires after as little as 3cm pieces.

This is achieved to hold the feeding continuous. Tire shredders are fully automatic and will be connected right to the pyrolysis plant. Hence, you’re never going to need to be concerned about the transferring process. After the materials are shredded, they can be sent in to the plant. Get small pyrolysis machine price here.

First, they undergo reactions with multiple reactors. This is achieved to convert the tires into oil gas. After cooling, the oil gas will then be pushed to some continuous feed for discharge. The waste tire pyrolysis plant also possesses its unique list of unique benefits.

Considering that the plant is continuous, PLC systems reduce the labor cost. This machine only requires a team of two as a way to function at its best. The plant incorporates multiple reactors, the original output is usually going to be higher. Due to the continuous discharging and feeding process, around 100 plenty of waste may be produced in just one day.

As we’ve previously mentioned, continuous operations produce a great energy and way to save time. Through the life of the heating reactor, the environment is heated indirectly. This preserves the entire lifespan of your reactor and prevents damage. Hence, your plant may have a long service life as well as the reactor will never have problems with any damages.

Since we conclude, we have just checked out the waste tire pyrolysis plant. These plants are useful since they is effective in reducing the waste created by old tires. They benefit humans and also the environment while they work continuously to process old tires. Visit the site: https://bestoncompany.com/es/tyre-pyrolysis-plant/.